Our products undergo rigorous testing in independent facilities in the UK to ensure compliance with international safety standards. All of our Jerry Cans are UN certified, offering our clients peace of mind that they are using products that meet the highest regulatory requirements.

Not content with just achieving the necessary Group II standard, we set out to demonstrate the quality and performance of our most popular 20L Jerry Cans and achieved the more exacting standards required for Group I.

The requirements of the UN standard can be downloaded by clicking the button below. In the UK, jerry cans also need to comply with PCR (2014) which is also available via the link button below.

The Jerry Can should be dropped in an orientation that is most likely to result in failure.

Group 2 Jerry Cans = Dropped, brim-full from 1.2m

Group 1 Jerry Cans = Dropped, brim-full from 1.8m

There must be no leakage, even after the pressure is neutralised by drilling a hole in the top of the Jerry Can when it is in a rest position.

PASSED at 1.8m

The Jerry Can and its closure should be restrained under water for 5 minutes while an internal air pressure is applied.

Requirement : Group I ≥ 30Kpa

Requirement : Group II ≥ 20Kpa

Tested to 40Kpa without any leakage

PASSED

The Jerry Can shall have an internal pressure applied for 5 minutes without leakage.

Group II Jerry Cans – Pressure ≥ 100kPa

Group I Jerry Cans – Pressure ≥ 250kPa

No leakage

PASSED at 270kPA

The Jerry Can should be subjected to a force on the top surface, equal to the mass of a 3m stack.

150Kgs without leakage

PASSED test to 250kgs

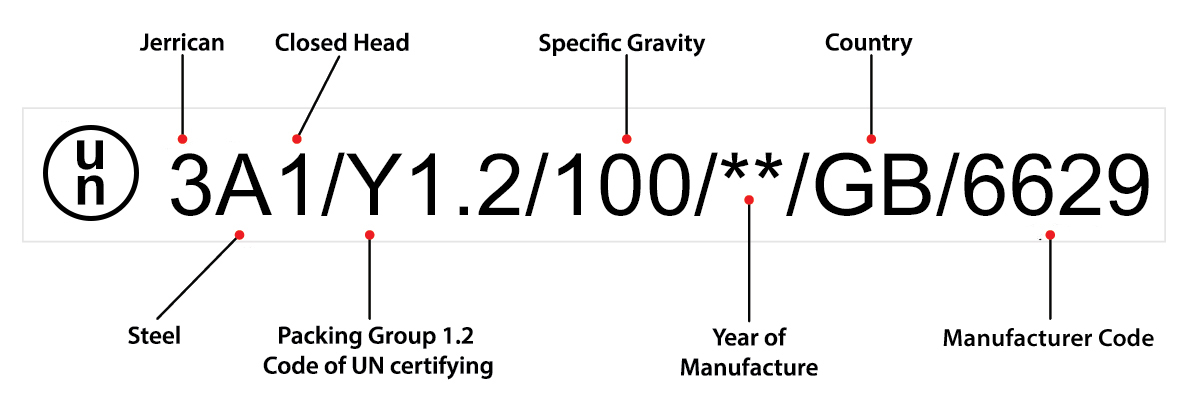

It is important to always check on the supply and source of jerry cans to ensure that they are certified to UN standards by checking the codes which should be embossed on the side of the can. If the can is certified in UK, it can also be verified on the VCA website.

The code on the certificate comprises of the sections below.

| Character | Description |

|---|---|

| Type of Package | 1 - Drums 2 – Barrels 3 - Jerricans 4 - Boxes 5 - Bags 6 - Composite Packagings |

| Material | A - Steel B - Aluminum C - Natural Wood D - Plywood F - Reconstituted Wood G - Fiberboard H - Plastic L - Textile M - Paper, Multiwall N - Metal other than Steel or Aluminum P - Glass, Porcelain or Stoneware |

| Category | 1 - Closed Head 2 - Open Head |

| Packing Group | X - Packing Groups I, II, and III Y - Packing Groups II and III Z - Packing Group III only |

| Maximum Gross Mass or Specific Gravity | Maximum Gross Mass - Solids or packagings that have inner packagings must be marked with the maximum gross mass (weight) in kilograms. Specific Gravity - Stand alone packagings intended to contain liquids must be marked with the specific gravity rounded down to the first decimal. |

| Solids or Inner Packaging | Solids - An "S" in upper case should follow the maximim gross mass. Liquids - Liquids should reflect the Hydrostatic test pressure in kPa (kilopascals), rounded down to the nearest 10 kPa. |

| Year of Manufacture | The last two digits of data indicate the year the packaging was manufactured. |

| Location of Manufacture | Country where the item was manufactured. |

| Manufacturer Code | Code for UN certifying agency or manufacturer. |

At Yates Steels, we take quality seriously. Our products undergo rigorous testing in independent facilities in the UK to ensure compliance with international safety standards. All of our jerry cans are UN certified, offering our clients peace of mind that they are using products that meet the highest regulatory requirements.

As well as UN certification , our jerry cans also comply with with PCR (2014) which is available here.

Confident in our own internal quality assurance, Yates Steels is also externally audited for customer confidence. We are ISO certified to ISO 9001 2015 Quality Management System as well at ISO 14001:2015 Environmental Management System. T

The factory is audited by SEDEX with annual SMETA unannounced independent inspection.

Yates Steels is committed to sustainability.

Our factory in India operates with a focus on reducing environmental impact and meeting ISO environmental standards and is is certified ISO 14001:2015 Environmental Management System.

We continually strive to reduce our carbon footprint through energy-efficient practices and waste-reduction strategies, supporting a greener, more sustainable future. This includes recent installations of roof top solar panels providing 100% of our electricity supply and ensuring we always use recycled material for our packaging.